This section will contain a number of things, for example, new items obtained and that is where I shall begin.

I received some new goodies yesterday which arrived from Adam (Cro fittings) . These consist of the Wakefield No.7 mechanical lubricators and the Gresley manifold, both to scale.

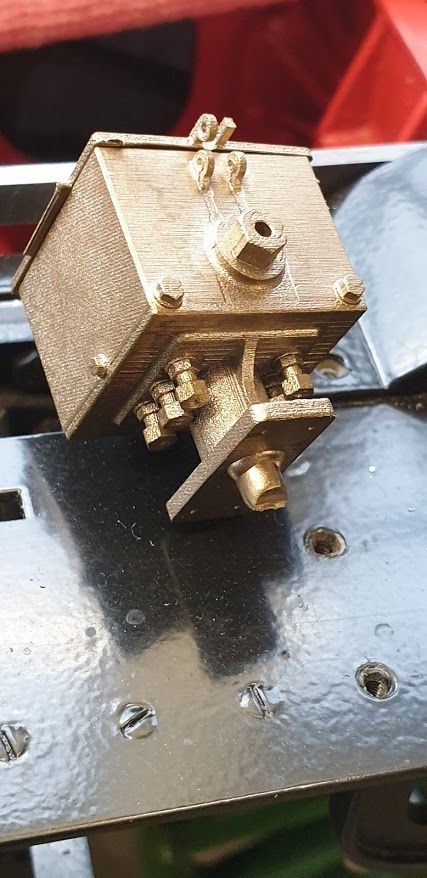

Lubricators first, here's a close up showing the level of detail which 3D printing can achieve, very impressive. A little of the step processing seen but I'll remove most of this and once painted I'd expect that most, if not all will no longer be visible. The quality of the detail is superb, you can read every word, my hand should give you an idea of the scale. These come with the hinge blocks already tapped 1mm for the pins which are also supplied. Since my smallest tap currently is 1.4 or is it 1.2mm? this was a welcome surprise.

The underside to show the 6 oil-way outlets, these are quite small but I'm hopeful of getting these to supply oil, I have already considered a possible mech to feed them, just need to draw it up and have a few R&D sessions. I know that a Fellow ~Model Engineer has successfully fitted pipe with 8BA sized flanges which is probably pretty close to these in size, perhaps even a little smaller.

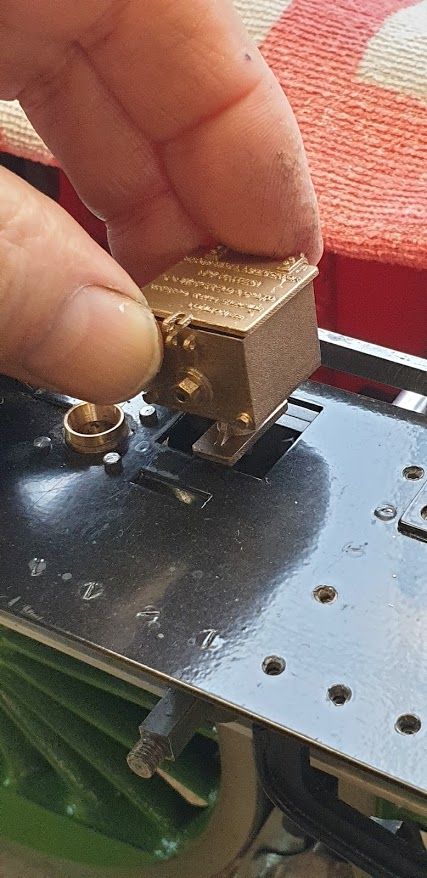

Here I have held one of the lubricators in it's proper location to take this picture. Alas I can't hold the operating arm at the same time, when it's all built the arm will drop through the slot which you can just see and connect to the operating arm below. This arm is attached to the back of the expansion link and also to a rod which connects the the other lubricators arm near the smokebox, all as per prototype. Some may think that these boxes are too small to be practical, well in fact they are about the same size as Don's drawing for his own design, perhaps even a fraction bigger. The trick is going to be to design a system which pumps oil to the 6 outlets...... did i mention how much I love a challenge?...

this is something that I have really been looking forward to getting. Here we have the scale manifold, drawn up by Adam specifically for my loco, although I do believe that Adam may have another in stock for any other true scale guys who may be considering the same...

First observations show that it's going to be tight although perhaps not as much as it looks. The prototype's manifold handles sit behind the water gauge fitting and it's top valves, although the manifold in general is higher up. I will look at this later once the boiler is back on the frames and the cab attached. I could raise the manifold on a spacer if there is room below the cab roof, if not I may need to get a little creative on the pipes running from the manifold otherwise it's perfect. Yes the handles won't be easy to operate when the loco is running, but then they shouldn't need to be, these are after all just isolators.