I commissioned Craig at '360 spin' (link on links page) to spin up the steel covers for the outside cylinder covers. I believe that these are a burnished steel on the prototype and therefore I have chosen stainless steel for the model, less work in keeping them bright. Today they are painted black.

Craig spun these to my dimensions and they are a perfect fit, they are spun from 1 mm stainless with the outside edge then being turned down to 0.5 mm thick to match the lip on the covers that I machined. I am very happy and impressed with Craig's work, even more so when he had no drawings to work from, just my notes via FB. They were also very well priced so I'm a happy man...:)

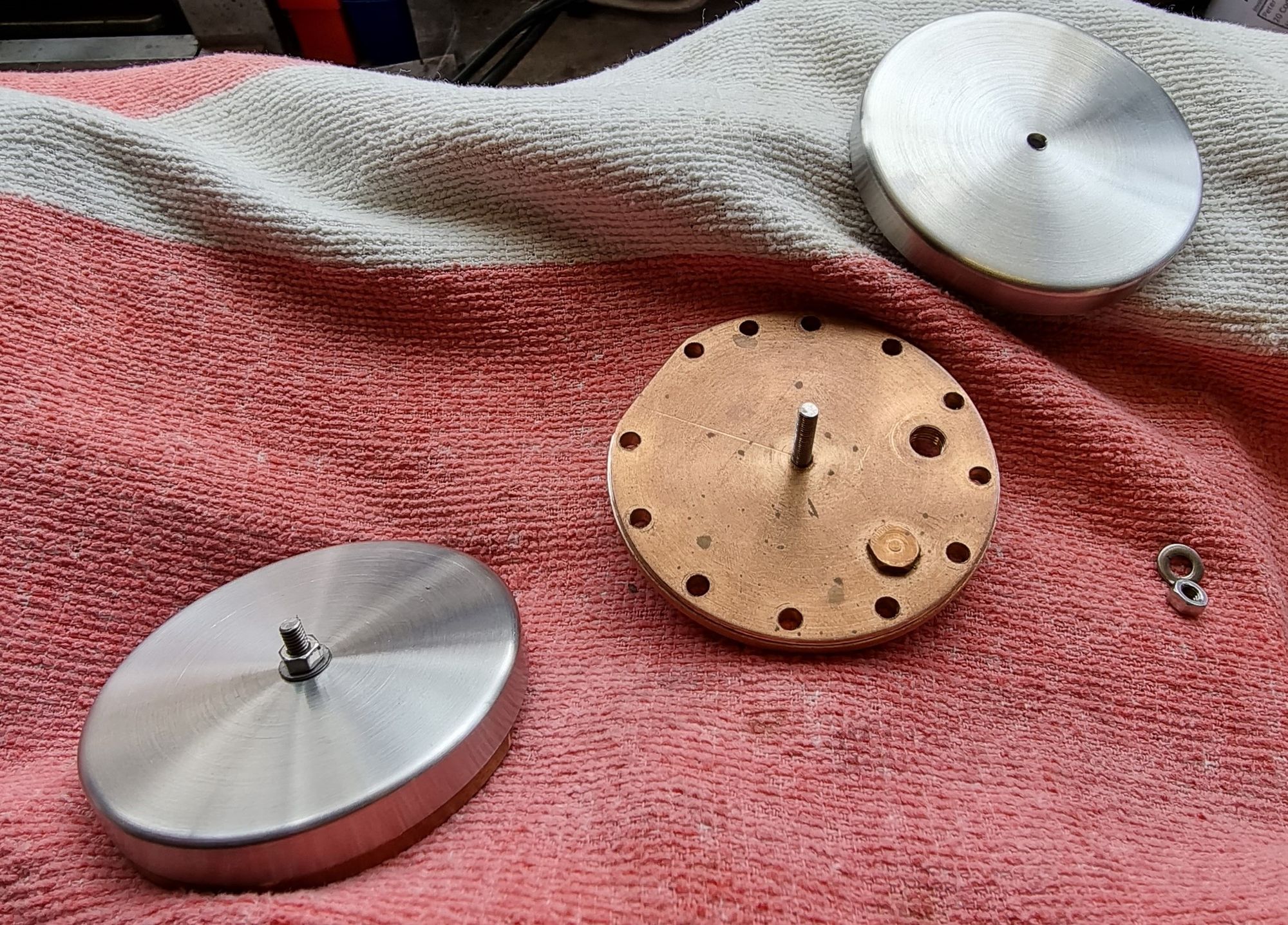

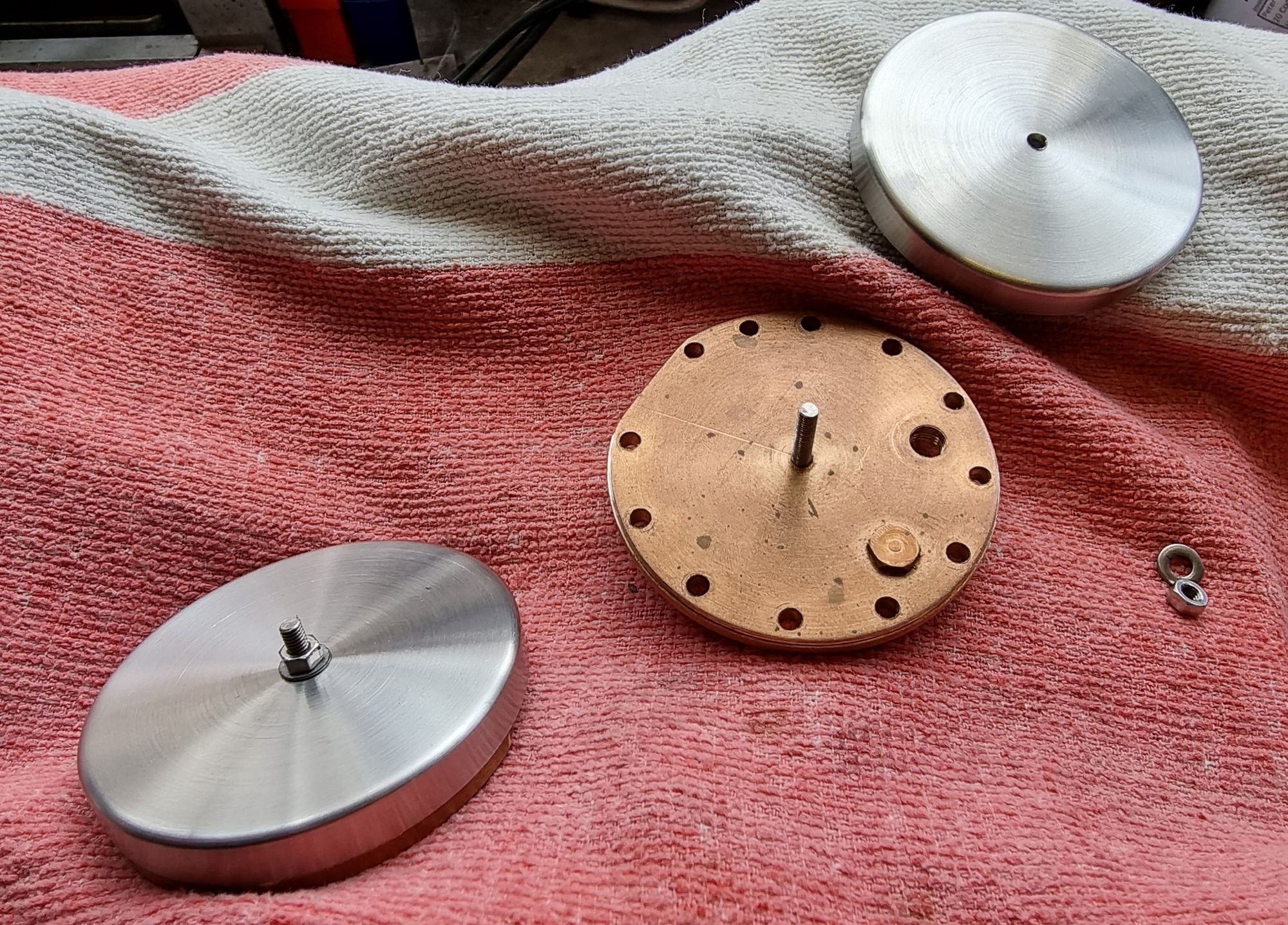

The picture below shows one cover fitted and the other resting beside it's cylinder cover. The 6BA stainless stud will be trimmed to length later. The depth of the covers are designed to follow full size as close as possible and also allow clearance for the cylinder cover studs/bolts beneath.

There are a couple of jobs to do before final fitting, those being to drill the hole for the cylinder relief valve to poke through and to machine the small flat section that can be seen top left of the bronze cylinder cover, this area butts up against the steam chest when fitted, these are of course 'handed'