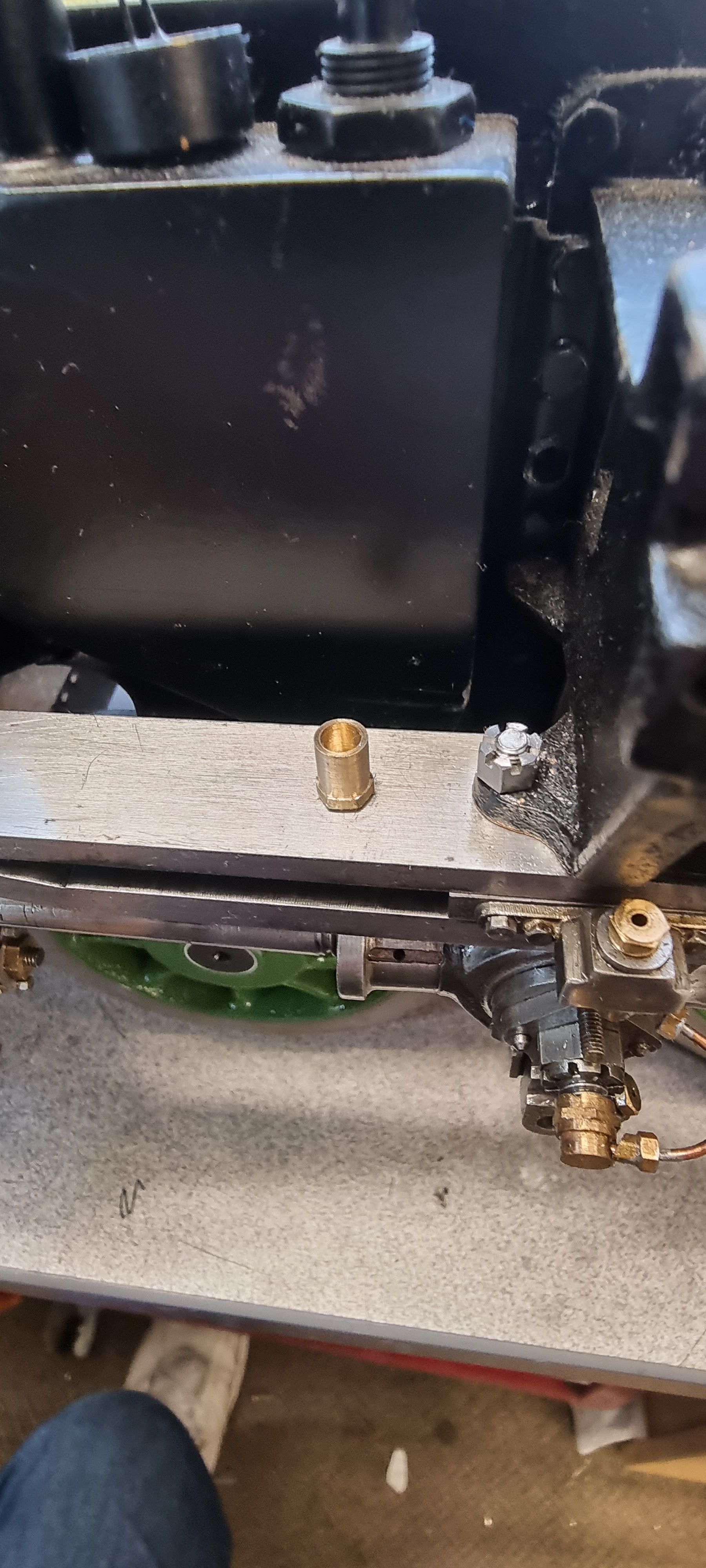

I have revisited the coupling/connecting rod oiling pots, they are the same design but the material has been changed from steel to brass. I had tried to find bronze 3/16 hex which would be as per prototype but after a few weeks searching in vain I have settled for brass, BTW, today FS has the BR steel button type pots although I have spotted the odd hex steel pot thrown in. Yes I could machine some round bronze bar to hex but life is short enough. I can always revisit these again once the model is finished.

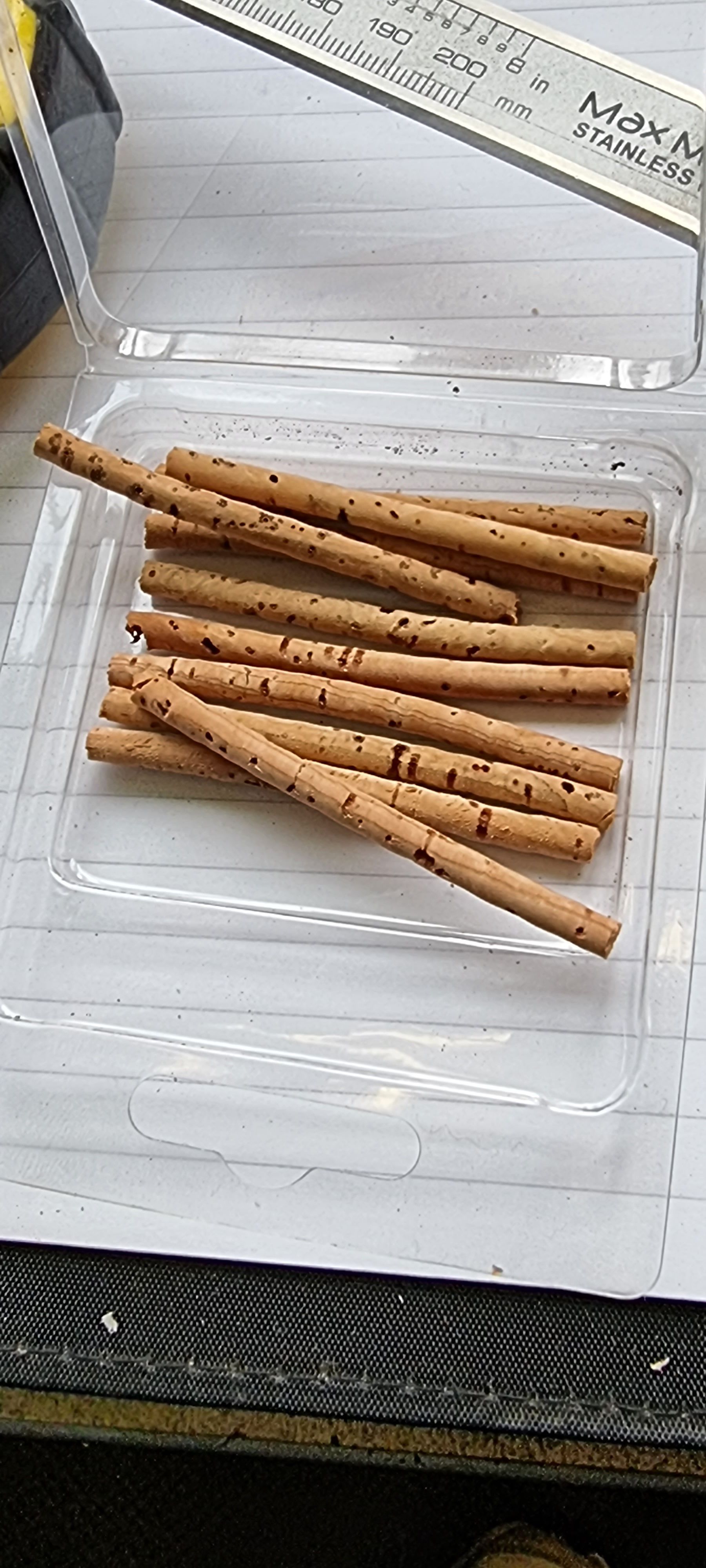

Another change is the tooth picks that were used to represent cork stoppers, I have now changed these to actual cork.

So how did I make the cork stoppers? these began life as 4mm dia sticks which I believe are used for fishing.

First picture shows the cork sticks in their packet, I found these on Amazon.

I tried a number of ways to get the taper, tried the lathe using a syringe needle held in the tailstock to support the tail and 180 grit paper but the lathe wasn't fast enough to do this effectively. I eventually found the best and quickest way was to use a hand drill resting on my lap while shaping it with the sandpaper.

Here is one of the corks so shaped, I soon found the best shape to both look right and fit into the oiling pot.

The oil pots themselves were plain turning, I tapped the opening 8 BA for the cork to screw into, the other end is threaded 3/16 x 40 to fit the rods, the bore is 1.8 mm. The cork is pretty flexible and does gain a good purchase into the pot. These should breath unaided to stop a vacuum building up and thus stopping the oil but I can push a syringe needle through the cork later is it's required

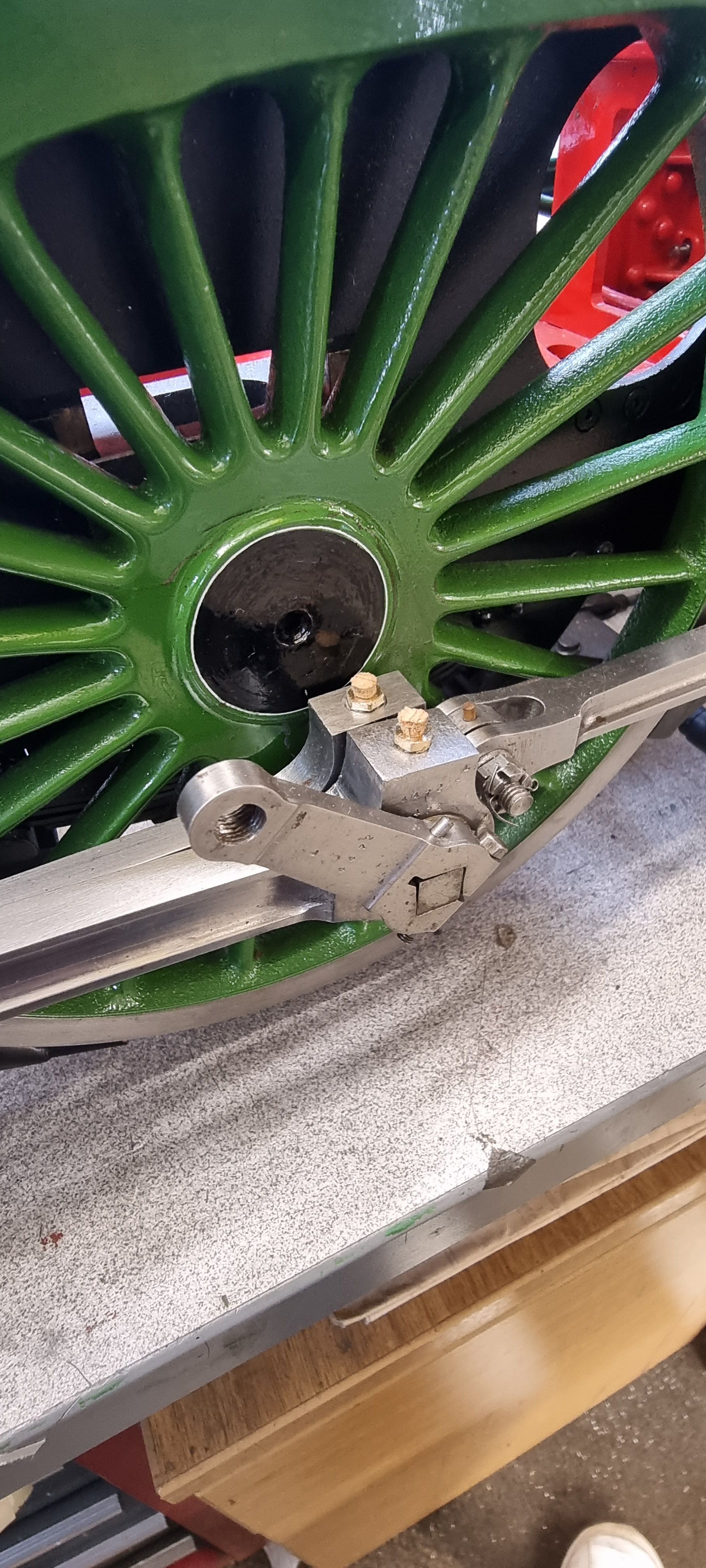

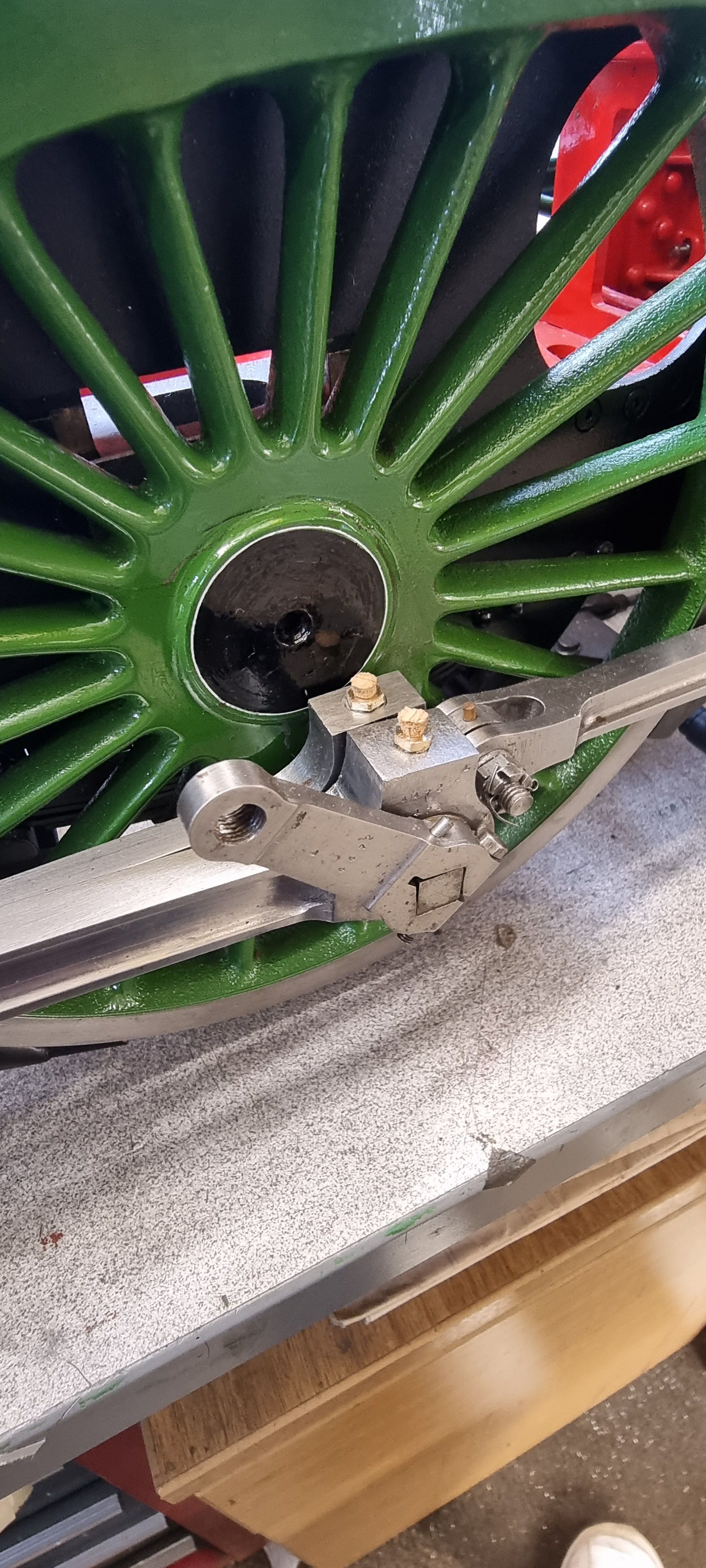

Here we see a close up showing two of the pots fitted to their rods, I found it best to fit the corks into the pots before fitting to the rods, the corks are easy to remove for oiling and if any fall out when running they only take a few minutes to make.

Next up is the slidebar oil pots, I have used modelers license for these and going with the earlier type which is still fitted to Fs's middle slidebar today but not the outside bars which have two individual oil pipes fitted. I'm not sure when these changed but think it was before 1938. The middle pot today has a hinged lid fitted, i can not see this in the outer pots, perhaps they have a sleeve like the expansion link oil pots. I'm going to leave the lids for now until i know how much clearance I have below the valve spindles for the outside cylinders and how much access i have to the middle cylinder.

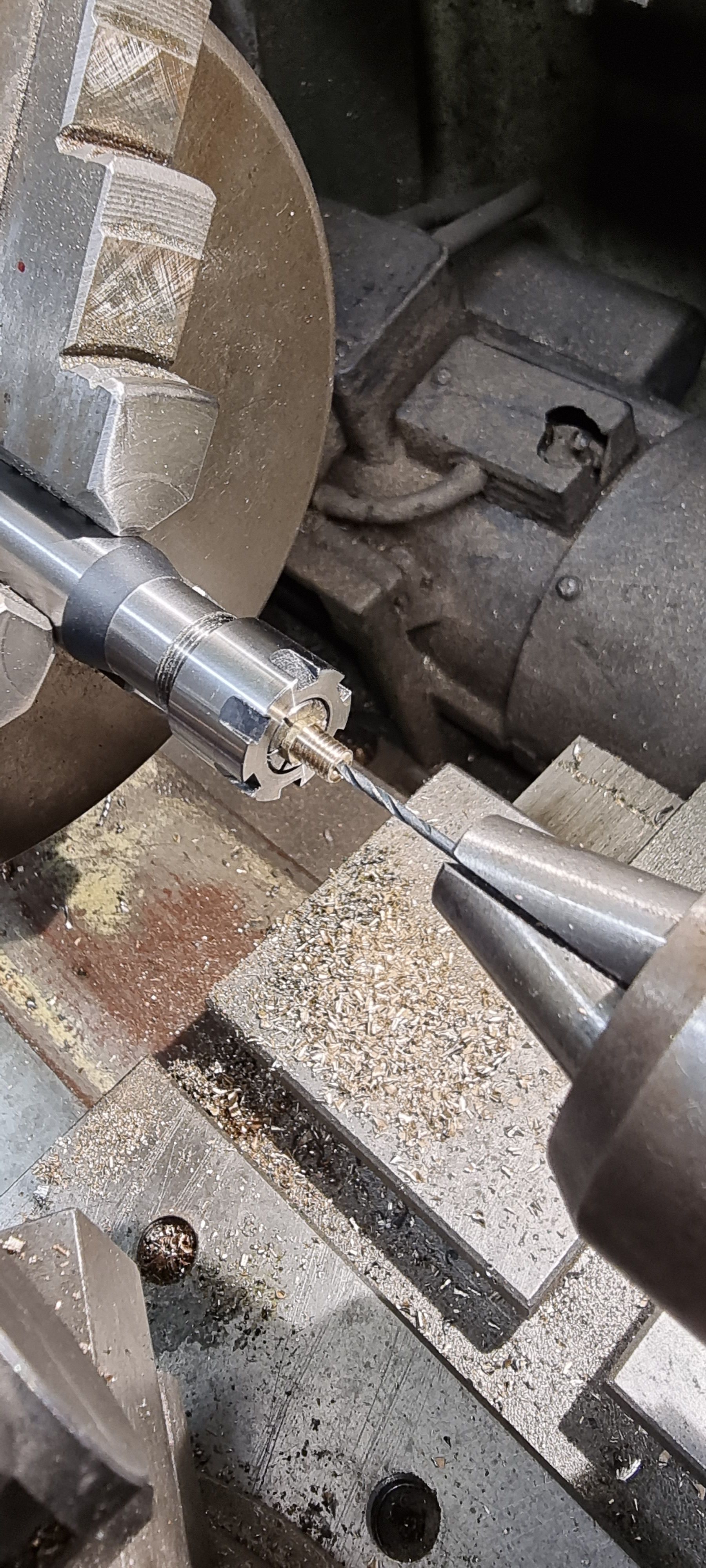

To turn the pots I used my small ER16 collet holder held in the 3 jaw which worked very well, these pots basically match that fitted to the inside connecting rod, the thread however is 5/32 x 40 instead of 3/16 x 40. I chose 1/8th for the well and 1.4 mm for the oil hole. The next picture shows one of the pots held in the collet chuck to have it's 1.4 mm bore drilled. Using the collet chuck made life easier to set the position of each pot to machine the 5/32 to length and keep the hex width the same.

Here we see the left hand oil pot fitted to it's slidebar, as I said I'll look at the lids later, I think that using these earlier type of oil pot will make life easier to control /ensure enough oil gets to the crosshead slippers.